Design

ABT Products offers an in-house design service that supports OEM manufacturers from concept through to production-ready structures. With extensive cab and safety-structure experience, our design team focuses on delivering practical, manufacturable solutions that meet performance requirements and integrate smoothly into your wider vehicle programme.

Using industry-standard software and proven processes, ABT helps reduce development time, improve build consistency and ensure designs are aligned with both safety expectations and real-world operating demands.

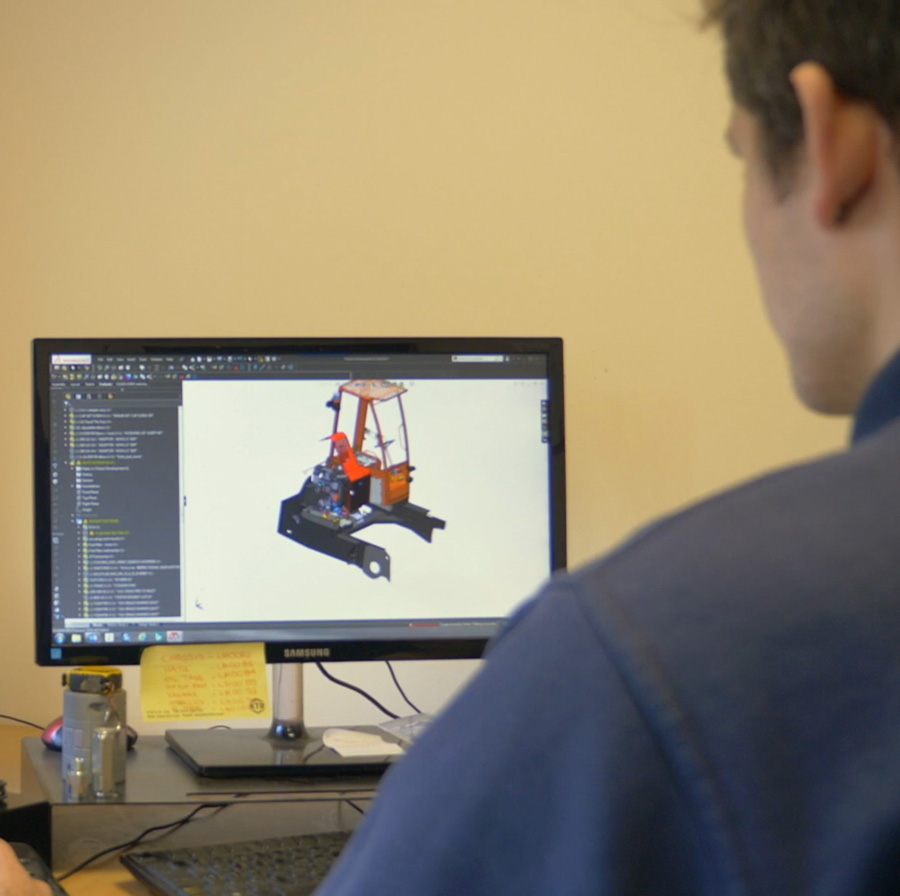

3D design in SolidWorks

ABT designs in 3D SolidWorks, with six seats available to support ongoing programmes and multiple projects. This allows us to develop detailed assemblies, refine designs efficiently, and collaborate effectively with customer engineering teams throughout the development cycle.

CAD/CAM capability with Radan

Alongside SolidWorks, ABT uses Radan CAD/CAM to support efficient manufacturing workflows. This helps ensure designs translate accurately into production, supporting repeatability, material efficiency and reliable output.

File compatibility and data exchange

We can work with a wide range of engineering file formats, making it easier to integrate with your existing systems and suppliers. ABT supports import and export of commonly used formats, including:

This flexibility helps speed up collaboration and keeps design information consistent across the supply chain.

Structural design and safety standards

ABT has deep experience in structural design, including the development of cabs and safety structures designed to meet international ROPS / FOPS / TOPS expectations. From early-stage design considerations through to test-aligned development, our team supports structures that are engineered for strength, durability and compliance.

get a free quote

Why choose ABT Products?

Backed by more than six decades of UK manufacturing excellence, we deliver high-quality chassis, vehicle cabins/operator environments, suspension components, roll bars, and complex fabricated assemblies.

End-to-end services

CAD design, ROPS/FOPS certification, tooling production, and assembly.

Industry Leading manufacturing capabilities spanning component production, welding, corrosion-resistant pre-treatment and painting, through to final assembly and delivery

Total supply chain solutions

We manage everything –from glass door furniture to engines, wiring looms, axles, and climate control systems –so you don’t have to.

Turnkey solutions

We specialise in full turn key delivery, supplying fully finished products built to your quality specifications, on time and anywhere in the world –empowering you to exceed your customers’ expectations

With our global capability we deliver finished products and spare parts anywhere in the world, providing a seamless and reliable service.

Surface preparation and finishing

End-to-end surface finishing solution combining automated shot blasting, advanced autophoretic (A-coat) immersion coating, and high-quality 2K electrostatic top coating. Our process accommodates large components—with shot blast capability ensuring uniform internal and external coverage, excellent corrosion resistance, and premium top-coat finishes. Finished part are fully integrated to deliver efficient coating solutions.